FASTACT

FAST-ACT is a combination of common metal oxides (MgO + TiO2) with a unique morphology. It has nanomaterial properties with a final particle size of nearly 5μm. The production process creates an altered, non-toxic molecular structure with large increase in porosity and surface area.

Neutralization

Real-Time

Covers

Vapours, Fumes & Liquids

Ready to use

No water required

Safe

Non-Toxic, Non-Corrosive

Description

FAST-ACT is a combination of common metal oxides (MgO + TiO2) with a unique morphology. It has nanomaterial properties with a final particle size of nearly 5μm. The production process creates an altered, non-toxic molecular structure with a large increase in porosity and surface area.

How Does It Work?

Nanomaterials, by nature, tend to agglomerate. Because the molecular structure of FAST-ACT is incomplete, it binds to any reactive substance using "ionic bonding." It utilizes the targeted chemical's ions to try and complete its own structure, resulting in the neutralization of many hazardous chemicals through a process now known as "destructive adsorption." The large surface area, with numerous corners and edges containing many unsaturated ions, makes it effective on liquids and vapors of hazardous compounds.

FAST-ACT literally binds and destroys the contacted chemical, resulting in a non-hazardous, neutralized by-product.

FAST-ACT residue is MgS after reaction with H2S.

| Neutralisation | Adsorption | Non Effective | ||

|---|---|---|---|---|

| CORROSIVE MATERIALS | VAPOUR HAZARDS | LIQUID SOLVENT SPILL | ||

| ACIDS | HALOGEN / HALIDES | ACIDS & CAUSTIC GASES | ALCOHOLS / PHENOLS | BIOLOGICALS |

| Inorganic and Organic | Acetyl Chloride | Hydrogen Chloride | Ethanol | Bacteria |

| Hydrochloric Acid | Chloroacetyl Chloride | Hydrogen Fluoride | Methanol | Viruses |

| Hydrofluoric Acid | Chlorine | Hydrogen Bromide | Allyl Alcohol | Spores |

| Nitric Acid | Chloroform | Nox/N204 | Nltrophenols | NUCLEAR |

| Phosphoric Acid | Hydrogen Bromide | Sulphur Dioxide | Chlorophenols | RADIOLOGICAL |

| Sulphuric Acid | Cyanogen Chloride | HEAVY METALS | ||

| Acetic Acid | Methylene Chloride | HALOGENS | CAUSTICS | SOLID WASTE |

| Methanesulfonic Acid | Carbon Tetrachloride | Chloride | Metal Hydroxides (aq) | |

| Ethanesulfonic Acid | TCE, PCE | Bromine | ||

| Benzenesulfonic Acid | Iodine | PETROCHEMICALS | ||

| Toluenesulfonic Acid | PHOSPHORUS | Diesel | ||

| Hydrogen sulfide (H2S) | Pesticides | VOLATILE ORGANICS | Gasoline | |

| DimethylmethylPhosphnate | Methyl Mercaption | Olis | ||

| BIS (2-CHLOROETHYL) SULFIDE | Paraoxon | Ethylene Oxide | ||

| Parathion | Formaldehyde | OTHERS | ||

| PINACOLYL | Phosgene | Acrylonltrlle | ||

| METHYLPHOSPHONOF LUORIDAT | SULPHUR | Arsine | Benzene | |

| 2-Chloroethyl Ethyl Sulfide | Hydrazine | |||

| O-ETHYL S | Methyl Mercaptan | CHLORINATED | Toluene | |

| (2-DISSOPROPYLAMINOETHYL) - | ORGANICS | Acroleln | ||

| MET HYLPHOSPHONOTHIOATE | PHENOLS | Acetyl Chloride | Methylhydrazlne* | |

| Nitrophenols | Chloroacetyl Chloride | Methyllsocynate* | ||

| CARBONYL COMPOUNDS | Chlorophenols | Chloroform | ||

| Aldehydes | Methylene Chloride | |||

| Ketones | CHEMICAL WARFARE AGENTS | |||

| Carboxylic Acids | Sulphur Mustard (HD) | |||

| Tabun (GA) | ||||

| NITROGEN COMPOUNDS | Sarin (GA) | |||

| Acetonitrile | Soman (GD) | |||

| Sodium Cyanide (AQ) | VX & H2S | |||

| 4-Vinylpyridine | ||||

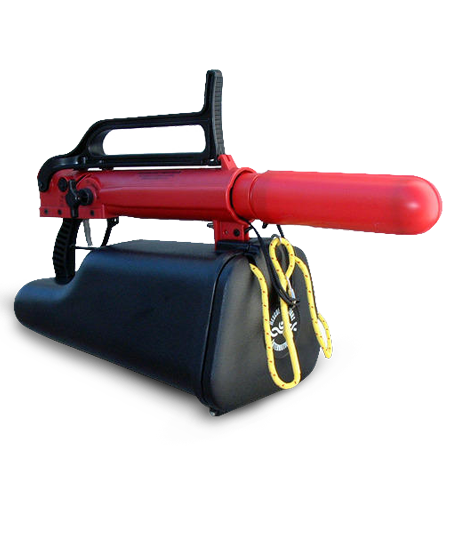

| Capacity | 1kg / 2kg / 4kg Decontamination Powder (Nanomaterials) in pressurized vessel |

|---|---|

| Operating Pressure of the container | 180 - 220 PSI (UP TO 15 BAR) |

| Discharge time | Not more than 2 min |

| Pressure gauge | Yes Provided (easy to read). 2Nos. |

| Gas used for pressurization | Nitrogen |

| Discharge Hose & Nozzle | Nozzle that can spray the powder evenly and easily and shall not get corroded / clogged on exposure to chlorinating compounds. |

| Container / Vessel | HDPE white color vessel Test pressure: 22 Bar and Burst pressure 55 Bar (Minimum) as per TC of Manufacturer or as per guidelines |

| Color and form of material / particles | White dry powder |

| Powder major ingredient | Dry Chemical powder formulation of non-toxic Nano crystalline metal oxides (primarily TiO2 and MgO) |

|---|---|

| Gross Weight (including powder) | 1kg Nanomaterials in 2kg Pressurized Cylinder - 2.1± 10% 2kg Nanomaterials in 6kg Pressurized Cylinder - 4.4± 10% 4kg Nanomaterials in 9kg Pressurized Cylinder - 6.7± 10% |

| Dimension (Height x Diameter) mm | 2kg - 410 x 125, 6kg - 570 x 178, 9kg - 640 x 210 |

| Test Reports | TNO, Netherlands / Beattle / SBCCOM or Lloyds for H2S neutralisation |

| Life of Decontamination Powder | 5 Years from the date of filling of vessel |

| Hose material as per EN standard (applicable for 6kg & 9kg pressurised cylinders) | EPDM |

Download Brouchure

Download Brouchure Enquiry Now

Enquiry Now

+91-11 49458800

+91-11 49458800 sales@askagroup.com

sales@askagroup.com